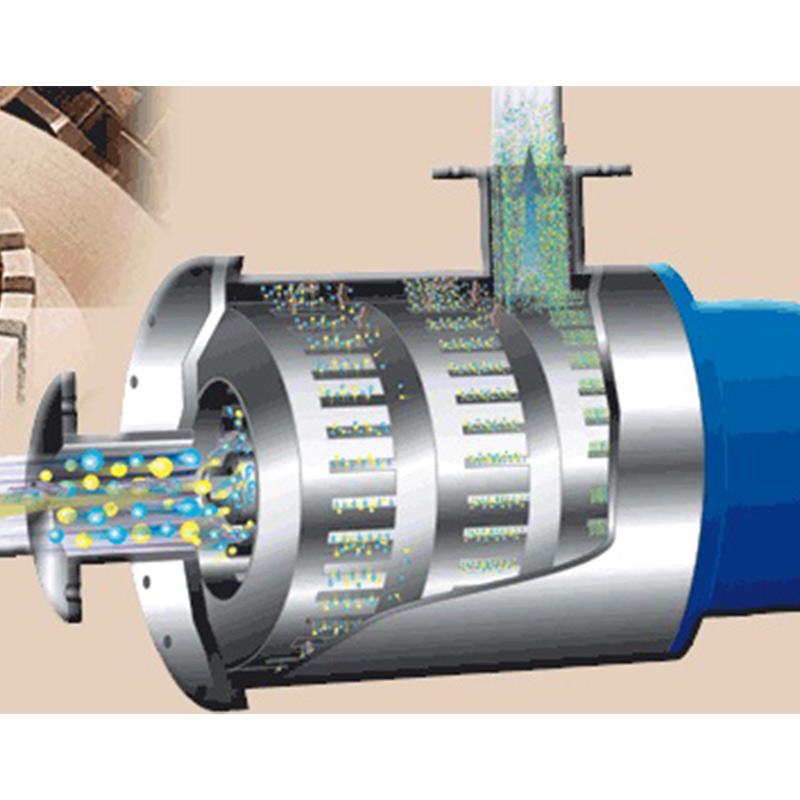

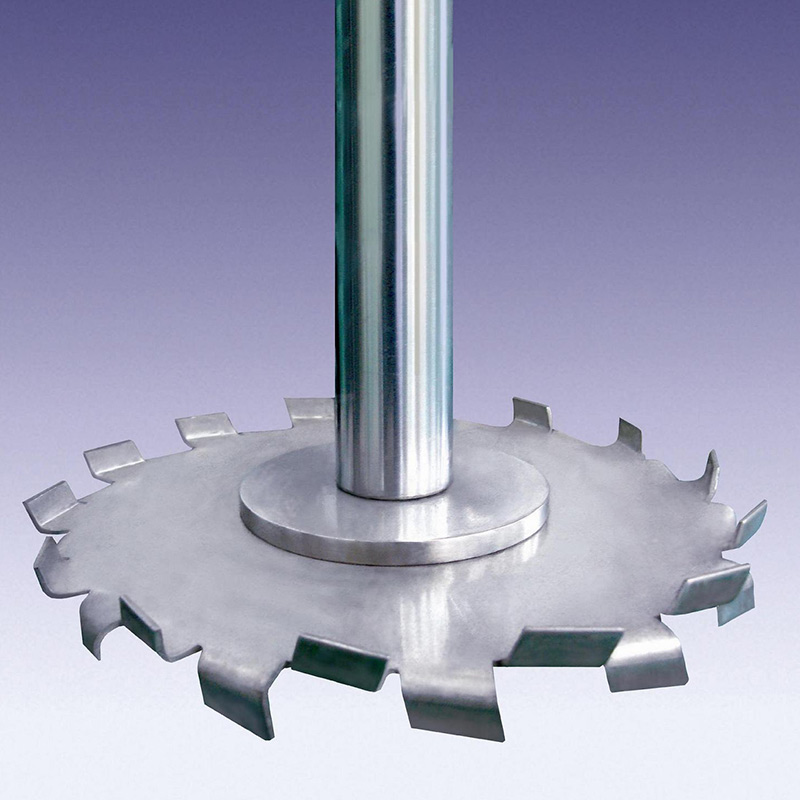

WebCapable of mass-producing high-quality, high-precision o particles. Supporting wide applications by setting mild dispersing, grinding, and optimal processing conditions. Reliable bead separation and stable use of microbeads (due to its adoption of the independently driven centrifugal separator) rEoI1ufetz9p WebFeatures Capable of mass-producing high-quality, high-precision o particles Supporting wide applications by setting mild dispersing, grinding, and optimal processing conditions Reliable bead separation and stable use of microbeads (due to its adoption of the independently driven centrifugal separator) Example of Mild Dispersing Ld63WchL417t WebChina Bead Mill manufacturers - Select 2023 high quality Bead Mill products in best price from certified Chinese Ball Mill, Grinding Mill suppliers, wholesalers and factory on Home Manufacturing & Processing Machinery Q45plLHawpyr WebDec 27, 2021 · The process of o milling, or o grinding, is the reduction of particles down to a very fine consistency through the use of wet grinding media mills. Reducing particles to sub-micron size presents unique challenges because the smaller the media you use, the smaller the mill screen needs to be, and the more susceptible that screen is to 6PGs9ngrM5XY

Get Price