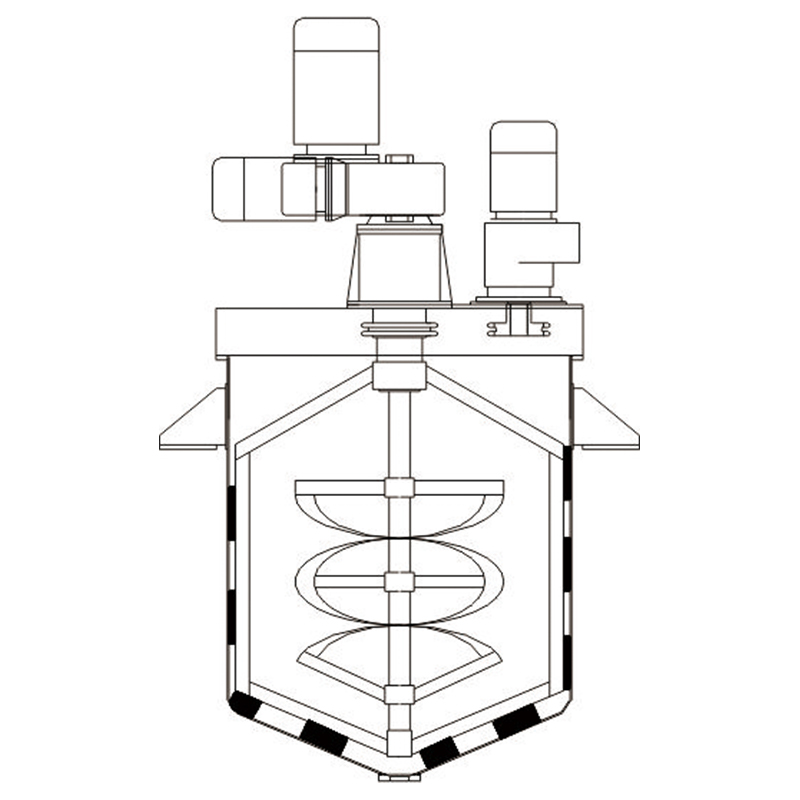

EquipmentFunctionOther instructionsPre-spray Treatment SystemRemove grease from metal surfaceBetter powder spraying of the workpiecePowder Spraying RoomAttach the powder to , etcCombination Baking ChannelPowder is sprayed onto the work pieceQuick color changeSuspended Transport SystemCarry out the conveyance of the workpieceChain suspension transportElectrical Control SystemThe power system of the production lineControl the entire production line operation sFEgmBLoSog9 Jinzong Machinery JRGP Series Vacuum Homogenizer Emulsifying Blender Machine Supplier*Main featuresOur JR vacuum homogenizer and emulsifierbines the newest-developed Germany technology and world-advanced unique function, its mainponents are imported originally from Germany. With new-structure, superior function, it is with fixed high-efficiency homogeneous emulsifier at the bottom-,Theplete-obscuration vacuum status with inner recycle system, All these make it very suitable for all kinds the production of cream and skin milk , and Compared to the traditional variety of emulsification equipment ,it has greatly improved the production efficiency and goods quality.*Application:The Vacuum mixer homogenizer use to produce cream, lotion,ointment in cosmetic, food, pharmaceutic industries.*Advantage:Our JRKA vacuum homogenizer and emulsifierbines the newest-developed Germany technology and world-advanced unique function, its mainponents are imported originally from Germany. With new-structure, superior function, it is with fixed high-efficiency homogeneous emulsifier at the bottom-,Theplete-obscuration vacuum status with inner recycle system, All these make it very suitable for all kinds the production of cream and skin milk , and Compared to the traditional variety of emulsification equipment ,it has greatly improved the production efficiency and goods quality.*Product Function Brief of Vacuum Homogenizing Emulsifying machineStainless steel: SUS316LAdopt hydraulic lift coverHigh-speed homogenizing blender(speed from 0-3000RPM, frequency speed regulation)Scraper blender speed: 0-83 e working procedure is operated in the condition of vacuum in order to prevent the materialing into being buble after high-speed blending and reach the request of sanitation and P cleanning system is equipped in this e contact part of vessel is made of SUS316L. other parts are made of SUS304.Mirror finish of the inside surface is ing SIMENS motor in order to ensure the stabilization of the ing Panasonic transducer.*Technical ParameterModelVolume of main pot(L(L))Dimension(mm)Weight(kg)Power(KW)Speed(rpm)Power(KW)Speed(rpm)JRGP/652400*JRGP/752600*JRGP-3/1002600*JRGP-200/1902900*JRGP-300-74150/260nformity of the data in the table due to technical improvement or customization, the real object shall prevail.*Features:High efficient emulsifier: it is a high efficient Germanpound homogeneous emulsifier with six-layer shear teeth of special structure, shearing more times, transient partial pressure up to 100Mpa above .its emulsification effect for materials which goes through the emulsifier is dozens of times than that ofmon ecision motion mechanism and cooling system: high efficiency, power loss is small, heterogeneous devices can work long time, the application of special process requirementsDead space-free multi-functional flow disturbance stirring system: it may effectively improve the stirring rate and mixing effects;Production of non-dead, out of less material residue: the JRKA homogeneous emulsifier type on the same machine, than the other types of emulsion is better;The cover of the main boiler can lift : to ensure that maintece and cleaning easy;All lifting system uses hydraulic mechanism to ensure the smooth movement, accurate, and security;Manual control, operation and easy maintece.*Semiautomatic or Automatic production lineOur semi-automatic series & Automatic series Production Line has win the acknolwledge by many big enterprise, such as LangQi, LIBY, Tianqi etc.Our production line is specially designed according to can provide from design, production, installment to raw material supply, which means theplete process of the project.*Packaging equipmentPlease let me know your bottles' size and shape, cap's size and shape, label's shape, we will make aplete solution according to your requirements for you!Different type vacuum homogenizing emulsifying mixer*After-sales service:1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.2> Provide professional after-sales service engineers to abroad installation and debugging.*ONE-STOP SERV is continuously researching, developing, upgrading and improving various products, striving to build the firs "one-stop" type cosmetic machinery shopping with machinery & equipment, cosmetic raw material, packing materials, technical consultation and other services*Providing technical support in the aspects of fieldmissioning and running of the products sold.*Field failure diagnosis and maintece.*Providing spare parts and fittings, maintece and servicing plans.*Choosing Jinzong Machinery is choosing professional technical support and good after-sales service.. is a professional manufacturer of cosmetic,chemical, biological & pharmaceutical machinery and equipment more than 20 years .Jinzong Machinery is a technology innovative enterprise focusing on machinery design, manufacturing and system oduct lines range from:1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, color paste mill, filling machine etc.2> Chemical Machinery: reactor, mixing equipment, separation equipment, storage tank, disperser, mill etc.3> Biological and Pharmaceutical Machinery: vacuum ointment machine, fermentation tank, sanitary stainless reactor,alcohol deposition can, collocation tank etc.*Our strength1. More than 20 years extensive experiencein the machinery manufacturing in Cosmetic and cheimical biological & pharmaceutical industry.2. Quality, 80% materials andponents are purchased from 3M, ABB, Siemens, Panasonic, Schneider. Up to now, all core machinery are with CE Certificate. We carry out products designing, manufacturing, assembling and detection fully in accordance with.3. Good reputation in industry. Many years are awarded "defend the contract heavy credit enterprise"4.Have a Professional after-sales service engineering rge scale plant. Currently, we have 2 processing bases, factory, covering a total area of more than 17,000 square meters,and factory,covering a total area of more than 30,000 square meters. Theuding large vertical lathe, 5-axis horizontal machining center, large planer type milling machine, automatic polishing machine, we produce more than 1000 sets of equipment every year CQpRonIAy8y3 Jinzong Machinery Jr Series Vacuum Homogenizer Emulsifying Blender Machine Supplier*Main featuresOur JR vacuum homogenizer and emulsifierbines the newest-developed Germany technology and world-advanced unique function, its mainponents are imported originally from Germany. With new-structure, superior function, it is with fixed high-efficiency homogeneous emulsifier at the bottom-,Theplete-obscuration vacuum status with inner recycle system, All these make it very suitable for all kinds the production of cream and skin milk , and Compared to the traditional variety of emulsification equipment ,it has greatly improved the production efficiency and goods quality.*Application:The Vacuum mixer homogenizer use to produce cream, lotion,ointment in cosmetic, food, pharmaceutic industries.*Advantage:Our JRKA vacuum homogenizer and emulsifierbines the newest-developed Germany technology and world-advanced unique function, its mainponents are imported originally from Germany. With new-structure, superior function, it is with fixed high-efficiency homogeneous emulsifier at the bottom-,Theplete-obscuration vacuum status with inner recycle system, All these make it very suitable for all kinds the production of cream and skin milk , and Compared to the traditional variety of emulsification equipment ,it has greatly improved the production efficiency and goods quality.*Product Function Brief of Vacuum Homogenizing Emulsifying machineStainless steel: SUS316LAdopt hydraulic lift coverHigh-speed homogenizing blender(speed from 0-3000RPM, frequency speed regulation)Scraper blender speed: 0-83 e working procedure is operated in the condition of vacuum in order to prevent the materialing into being buble after high-speed blending and reach the request of sanitation and P cleanning system is equipped in this e contact part of vessel is made of SUS316L. other parts are made of SUS304.Mirror finish of the inside surface is ing SIMENS motor in order to ensure the stabilization of the ing Panasonic transducer.*Technical ParameterModelVolume of main pot(L(L))Dimension(mm)Weight(kg)Power(KW)Speed(rpm)Power(KW)Speed(rpm)JR-3/1002600*JR-200/1902800*JR-300-74150/2602900*JR/460nformity of the data in the table due to technical improvement or customization, the real object shall prevail.*Features:High efficient emulsifier: it is a high efficient Germanpound homogeneous emulsifier with six-layer shear teeth of special structure, shearing more times, transient partial pressure up to 100Mpa above .its emulsification effect for materials which goes through the emulsifier is dozens of times than that ofmon ecision motion mechanism and cooling system: high efficiency, power loss is small, heterogeneous devices can work long time, the application of special process requirementsDead space-free multi-functional flow disturbance stirring system: it may effectively improve the stirring rate and mixing effects;Production of non-dead, out of less material residue: the JRKA homogeneous emulsifier type on the same machine, than the other types of emulsion is better;The cover of the main boiler can lift : to ensure that maintece and cleaning easy;All lifting system uses hydraulic mechanism to ensure the smooth movement, accurate, and security;Manual control, operation and easy maintece.*Semiautomatic or Automatic production lineOur semi-automatic series & Automatic series Production Line has win the acknolwledge by many big enterprise, such as LangQi, LIBY, Tianqi etc.Our production line is specially designed according to can provide from design, production, installment to raw material supply, which means theplete process of the project.*Packaging equipmentPlease let me know your bottles' size and shape, cap's size and shape, label's shape, we will make aplete solution according to your requirements for you!Different type vacuum homogenizing emulsifying mixer*After-sales service:1> one year from date of delivery, if any spare parts be broken within warranty and not caused by improperly operation, we would offer the new parts for free.2> Provide professional after-sales service engineers to abroad installation and debugging.*ONE-STOP SERV is continuously researching, developing, upgrading and improving various products, striving to build the firs "one-stop" type cosmetic machinery shopping with machinery & equipment, cosmetic raw material, packing materials, technical consultation and other services*Providing technical support in the aspects of fieldmissioning and running of the products sold.*Field failure diagnosis and maintece.*Providing spare parts and fittings, maintece and servicing plans.*Choosing Jinzong Machinery is choosing professional technical support and good after-sales service.. is a professional manufacturer of cosmetic,chemical, biological & pharmaceutical machinery and equipment more than 20 years .Jinzong Machinery is a technology innovative enterprise focusing on machinery design, manufacturing and system oduct lines range from:1> Cosmetic Machinery: water treatment ,vacuum emulsifying machine,liquid detergent mixing machine,storage tank,solid soap making machine,perfume making machine, color paste mill, filling machine etc.2> Chemical Machinery: reactor, mixing equipment, separation equipment, storage tank, disperser, mill etc.3> Biological and Pharmaceutical Machinery: vacuum ointment machine, fermentation tank, sanitary stainless reactor,alcohol deposition can, collocation tank etc.*Our strength1. More than 20 years extensive experiencein the machinery manufacturing in Cosmetic and cheimical biological & pharmaceutical industry.2. Quality, 80% materials andponents are purchased from 3M, ABB, Siemens, Panasonic, Schneider. Up to now, all core machinery are with CE Certificate. We carry out products designing, manufacturing, assembling and detection fully in accordance with.3. Good reputation in industry. Many years are awarded "defend the contract heavy credit enterprise"4.Have a Professional after-sales service engineering rge scale plant. Currently, we have 2 processing bases, factory, covering a total area of more than 17,000 square meters,and factory,covering a total area of more than 30,000 square meters. Theuding large vertical lathe, 5-axis horizontal machining center, large planer type milling machine, automatic polishing machine, we produce more than 1000 sets of equipment every year jGdNHCGP5nNO :Vacuum homogeneous emulsifying machine (top homogenizer)is an ideal option to produce highgrade skin care products, pharmacy ointment,and many other kinds of creams which need to be very soft and smooth. It has the functions of heating, mixing, scraping, rotating at different speeds and vacuum has a very wide application from cosmetics (skin cream, hair gel, lotion etc) and food (jam, chocolate, sauces etc) to pharmacy (ointment, syrup, paste) and chemicals(painting, adhesives, detergents).Advantages:Our JRK vacuum homogenizer and emulsifierbines the newest-developed Germany technology and world-advanced unique function, its mainponents are imported originally from Germany. With new-structure, superior function, it is with fixed high-efficiency homogeneous emulsifier at the bottom-,Theplete-obscuration vacuum status with inner recycle system, All these make it very suitable for all kinds the production of cream and skin milk , and Compared to the traditional variety of emulsification equipment ,it has greatly improved the production efficiency and goods quality.Features:1.High efficient emulsifier: it is a high efficient Germanpound homogeneous emulsifier with six-layer shear teeth of special structure, shearing more times, transient partial pressure up to 100Mpa above .its emulsification effect for materials which goes through the emulsifier is dozens of times than that ofmon ecision motion mechanism and cooling system: high efficiency, power loss is small, heterogeneous devices can work long time, the application of special process ad space-free multi-functional flow disturbance stirring system: it may effectively improve the stirring rate and mixing effects;oduction of non-dead, out of less material residue: the JRK homogeneous emulsifier type on the same machine, than the other types of emulsion is better;e cover of the main boiler can lift : to ensure that maintece and cleaning easy;l lifting system uses hydraulic mechanism to ensure the smooth movement, accurate, and security;nual control, operation and easy in boiler has the vacuum pressure of -0.08Mpa, the speed of rake stirrer is 7~60rpm with frequency control. The bottom homogenizer's revolution speed has 1400 and 2800 rpm two gears. It proves to be the perfect device for manufacturing medium&high-grade ointment and honey products.Technical Parameter:ModelVolume of main pot(L(L))Dimension(mm)Weight(kg)Power(KW)Speed(rpm)Power(KW)Speed(rpm)JRK/652400*JRK/752600*JRK-3/1002600*JRK-200/1902900*JRK-300-74150/2nformity of the data in the table due to technical improvement or customization, the real object shall oduct Show:Production Process:Why Choose US:---Solemn Commitment1,We have a professional technical team to design the best process and program for you.2,Insist on updating products regularly.3,24-hour telephone feedback on the solution, and send someone to handle it online.---Pre-sale serviceProvide detailed information for customers to understand the equipment's performance and scope of application. The equipment plan proposed by the customer can also be customized according to the actual requirements of the customer---InstallationAfter the equipment is shipped to the production site, we will provide tutorials or remote guidance for installation andmissioning; we can send engineers to the site to provide services according to the contract.---Lifetime warrantyLifelong tracking service, providing the latest technical support in real time. Machine parts andponents are available all year round to meet customer's needs and reduce waiting time; for equipment that exceeds the one-year warranty, only the cost of the parts will be charged for the replacement of damaged parts. A diversified online after-sales service platform is provided, Customers canmunicate with us via email, phone, whatsapp, WeChat, QQ, etc.Wee to Visit Our Factory:Shipment:Q&A:1.Why your machine similar with other supplier?We are manufacturer and had been in this industry for more than 20 years, with more than 6 years export experience. We design machines by ourselves with advanced technology. Appearance just a part of machine, service and quality is more important than it.2.I'm new in our industry, but I'm planning to setup a factory, What can I do?We can suggest customer the most suitable machine according to their formula, Raw material. Manufacturing- Installation- Training- Maintece- Technical Support. We can introduce you supplier of raw material, bottles, labels etc. We could take you to our customer's factory to learn how they produce. We could customize machines according to your real need, We could send our engineer to your factory to install machines and train your worker of Operation and maintece. Any more requests. Just let us know.3.What kind of machines can you supply to customer?We could offer various kinds of machines and whole production line.(1)Cream, paste Products:In cosmetic industry: face cream,body cream, washing cream, vaseline etcIn food industry industry: sauce, ketchup, tomato paste, mayonnaise, mustard, chocolate etc;In chemical industry: welding paste,ink, paint,pigment oduction line for them: RO water treatment- vacuum emulsifying machine- storage tanks- filling machine-capping machine- labeling machine- conveyor belt- inkjet printer- sealing machine-shrinking machine etc.(2)Liquid products:Shampoo, lotion, liquid soap, detergent,juice,solution etc;Production line for them: RO water treatment - liquid wash mixer- - storage tanks- filling machine-capping machine- labeling machine- conveyor belt- inkjet printer- sealing machine-shrinking machine etc;(3)Make-up products:Lipstick, lip gloss, nail polish, marscara etcMachines for them: homogenizer mixer, colliod mill, lipstick filling machine, frezzing machine.4.What equipment can Jinzong manufacture?(1) Vacuum homogenizer Emulsifying mixer(2)Liquid washing homogenizing mixer(3) Water treatment equipment (RO system)(4)Perfume maker(5)Anti-corrosion equipment and inkjet printer(6)Liquid filling and screw-cap sealing machines(7) storage Tanks(8) Laboratory equipment(9)Fi.(1)A professional manufacturer producing daily-use chemicals, medic 1999. We undertake equipment design, manufacture, installation, maintece, technical improvement support, technical consultancy and other services.(2)Our machines reach the GMP standards and CE certificate requirements. We attend many international trade fairs every year. By far, our products have been exported to over 50 countries all over the world and received much praise from them. Many customers be our long term business partners as well as good friends after the first cooperation.(3)We create value for customers. We not only provide installation service, but also help customers design and select equipment according to existing sites. After-sales department specifically organizes clients to carry out debugging.(4)The after-sales hotline is open the whole day and willing to provide consulting service for you. We value the good relationships with customers. Nt42LSDOsvEK

Get Price